Reciprocating Pumps in Onshore Oilfields: A Comprehensive Overview

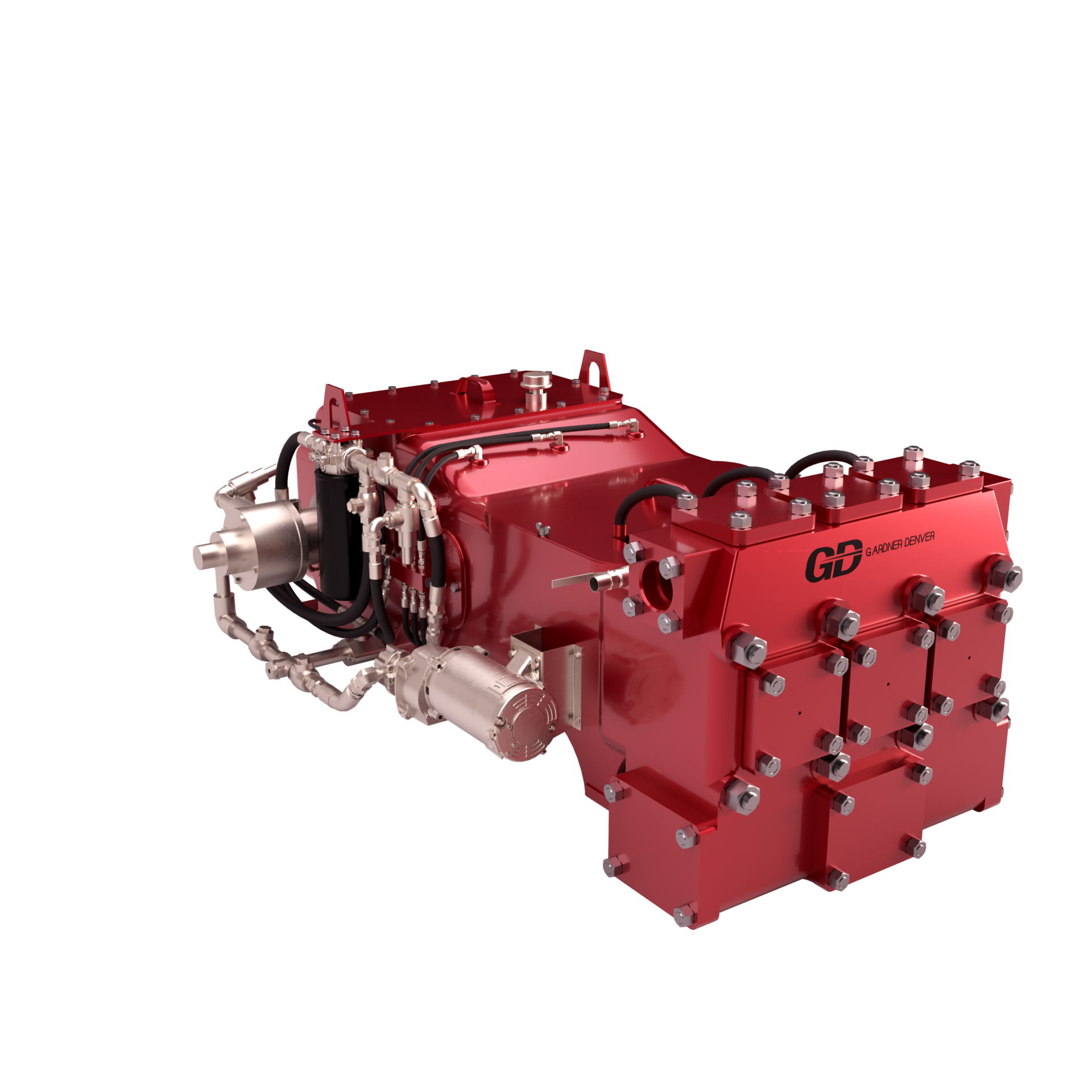

Power Flow supplies reciprocating pumps from manufacturers like Gardner Denver, Ingersoll Rand, Kerr Pumps, and Weatherford, known for their API 674 compliance and reliability in oilfield applications.

Reciprocating pumps play a critical role in the operations of onshore oilfields, where the transportation and control of fluids are essential to the extraction and processing of crude oil. These pumps, a subset of positive displacement pumps, move fluid by trapping a fixed amount in a chamber and then displacing it using a piston to move the liquid through various valves and pipes. Let’s delve into how reciprocating pumps function, their applications, types, and the advantages and disadvantages they bring to the oilfield industry.

What Are Reciprocating Pumps?

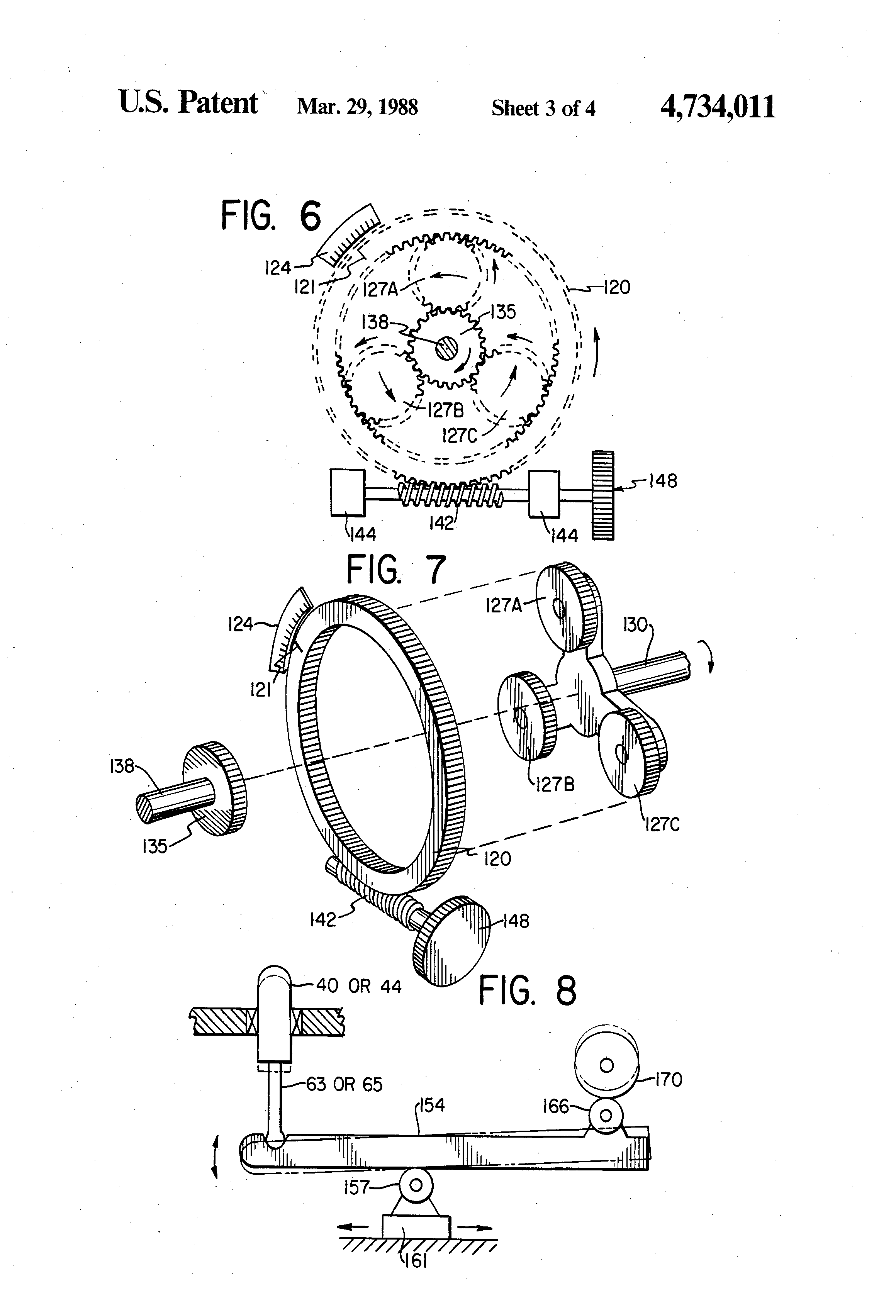

Reciprocating pumps are positive displacement pumps that operate using a back-and-forth motion known as reciprocating motion.

In this pump, a piston diaphragm or plunger moves within a cylinder to create pressure, which pulls fluid into the pump via a suction pipe and pushes it out through a delivery pipe.

The pressure generated ensures the liquid is transferred regardless of external pressure conditions, making reciprocating pumps particularly useful in oilfield operations, where managing heavy or viscous fluids is required.

Types of Reciprocating Pumps

Reciprocating pumps come in several designs tailored to specific industrial needs. The most common types include:

- Piston Pumps: These use a piston to move fluid through the system. They are often employed where high pressure is needed.

- Plunger Pumps: In this type, the plunger moves fluid by creating a seal between the chamber and the liquid.

- Diaphragm Pumps: These pumps use a flexible diaphragm instead of a piston or plunger to displace fluid. They are particularly useful for handling corrosive or abrasive liquids since the fluid does not contact the pump’s internal parts.

Components of a Reciprocating Pump

The critical components of a reciprocating pump include:

- Suction Valve: This valve opens to allow fluid into the pump when the piston moves in a downward motion.

- Delivery Valve: As the piston moves upward, the fluid is pushed out through this valve.

- Crank and Connecting Rod: These mechanical components convert the rotary motion from a power source (such as an electric motor or engine) into the back-and-forth movement needed for reciprocation.

- Suction and Delivery Pipes: The suction pipe brings fluid into the pump, while the delivery pipe moves the fluid out to the next stage of the process.

Application of Reciprocating Pumps in Oilfields

Reciprocating pumps are commonly used in onshore oilfields because they handle varying fluid viscosities, high-pressure environments, and precise flow control. They are employed in various tasks, including:

- Crude Oil Transfer: Moving oil from one point to another, often from wells to processing facilities.

- Water Treatment: Used in oilfield water management, these pumps handle wastewater or brine in drilling operations.

- Chemical Injection: Reciprocating pumps deliver precise quantities of chemicals needed for well treatments or refining processes.

Advantages of Reciprocating Pumps

There are several key benefits to using reciprocating pumps in onshore oilfields:

1. High Pressure: Reciprocating pumps can deliver fluids at high pressures, making them ideal for oil extraction processes that require significant force.

2. Versatility: These pumps can handle a wide variety of fluids, from water to viscous crude oil.

3. Precise Flow Control: Reciprocating pumps allow for accurate control of flow rates, essential for tasks like chemical dosing or water injection.

Disadvantages of Reciprocating Pumps

Despite their advantages, reciprocating pumps also have a few drawbacks:

1. Complex Design: The involvement of multiple moving parts such as the crank and connecting rod increases the chance of mechanical failure and requires regular maintenance.

2. Pulsating Flow: Reciprocating pumps can produce a pulsating flow, which may require additional components like dampeners to smooth out the delivery.

3. High Initial Cost: These pumps can be expensive to install due to their complex designs and high-pressure capabilities.

Reciprocating Pumps and Water Treatment in Oilfields

In addition to oil handling, reciprocating pumps are also used in water treatment applications. Onshore oilfields produce large quantities of wastewater, and reciprocating pumps help transport this fluid for treatment and reinjection into wells or disposal. The diaphragm pump type is particularly effective in this application because it can handle chemically aggressive fluids without damage.

Conclusion

Reciprocating pumps, including diaphragm pumps, piston pumps, and plunger pumps, are essential tools in onshore oilfield operations. Their ability to handle high pressure, control fluid flow precisely, and work with various fluid types makes them indispensable. However, like any technology, they come with challenges, including mechanical complexity and pulsating flow issues. Nevertheless, their widespread application in water treatment, crude oil transport, and chemical injection underscores their significance in the energy sector.

- Reciprocating pumps are a necessary component for high-pressure applications in the oil and gas industry, such as well stimulation, water reinjection, and fluid transfer over long pipelines.

- Compared to centrifugal pumps, reciprocating pumps are more forgiving of varying fluid compositions and can handle solids, but they create pulsations that can damage downstream instrumentation and piping.

- Selecting the right reciprocating pump requires evaluating factors like pressure, flow rate, and fluid composition to ensure the pump can handle the application while minimizing pulsation issues.

Weatherford Mud Pumps

- Horizontal multiplex pumps with a traditional packed plunger pump designed to basic compliance of API 674.

- Features pressure ranges from 500 psi to 11,000 psi and flow ranges to 57,000 BFPD.

- Pumps from 5 input horsepower rating to 1600 HP. Temperature ranges extend from cryogenic to 500° F.

- Mud pumps to 3000 horsepower

Read more about Weatherford production pumps here.

Kerr Pumps

There are some key advantages of Kerr pumps according Power Flow’s experience in the oilfield supply business:

- Kerr is a smaller, lesser-known pump manufacturer compared to larger players like Gardner Denver and Weatherford, but they offer a cheaper and faster delivery option.

- Kerr has a large installed base of over 35,000 pumps worldwide, providing niche name recognition and spare parts availability.

- Kerr pumps can be a good alternative option for customers looking for a lower-cost solution, especially if they are in a hurry or have a specific application where the Kerr pump can meet their needs.

- However, Kerr is still considered a “third or fourth tier” choice compared to the more well-known pump brands, as customers may be less comfortable with the Kerr name.

- Designed in compliance to API-674

- More than 100 Standard Models

- 5 – 625 BHP

- Up to 600 GPM (Gallons Per Minute)/21,000 BPD (Barrels Per Day)

- Discharge pressure to 15,000 psi (1035 Bar)

- Kerr Fluid End Options Include: Ductile Iron, Aluminum Bronze, Carbon Steel, Forged Stainless Steel & Duplex Stainless Steel

- All Forged / Cast Steel Fluid Ends can be Equipped with Flanges (Upon Request)

Read about Kerr Pumps click here

Duplex Double-Acting Piston Pump Design

- Slow speed piston pumps for high volume or high viscosity fluids (mud, crude oil and drilling fluids).

- Heavy duty construction for oilfield use, cast iron fluid end and power end.

- Flow rates from 100 USGPM (379 LPM) to 680 USGPM (2574 LPM)

- Pressures to 1500 psi (105 Bar)

Read more about WEI duplex double acting pumps here.

High-Pressure Pumps

- Power Flow handles GD Energy’s (Subsidiary of Gardner Denver) reciprocating plunger and piston pumps:

- Focusing on the Oilfield Production & Industrial Pumps

- Waterjetting pumps

- And all pump parts

For Fluid Pressures Up to 2,500 PSI

Gardner Denver manufactures high-pressure pumps, specifically for the fracking industry, where fluids need to be pumped at pressures over 7,500 PSI to break through geological formations.

A lesser-known, high-quality brand is Kerr Pumps. Their high-pressure pumps can operate at pressures over 2,500 PSI.