Reciprocating pumps are also referred to as high-pressure pumps. They manage fluid pressures up to 2,500 PSI.

High-pressure applications include:

well stimulation

water reinjection

fluid transfer over long pipelines

High-Pressure Pumps in the Onshore Oilfield Market

High-pressure pumps are critical components in the onshore oilfield market, enabling a variety of essential operations from oil extraction to fluid management. These pumps are designed to handle the intense pressures required in oilfield environments, ensuring smooth, efficient, and safe transportation of fluids. The robust nature of high-pressure pumps makes them indispensable for challenging tasks such as well stimulation, water reinjection, and fluid transfer over long pipelines.

Well Stimulation

Well stimulation is a crucial process in oil extraction, particularly in onshore oilfields where reservoirs can lose pressure over time or have lower permeability. High-pressure pumps are used to inject fluids into the wellbore to enhance oil flow by either fracturing the surrounding rock (hydraulic fracturing) or cleaning out the well to remove obstructions that block the flow of hydrocarbons.

During hydraulic fracturing, for instance, high-pressure pumps deliver a mixture of water, sand, and chemicals deep into the well at pressures high enough to crack the rock formation, creating pathways for oil and gas to flow freely to the surface. Without the force provided by these pumps, it would be impossible to achieve the desired reservoir stimulation and recovery rates in mature or low-permeability wells.

Water Reinjection

In many oilfields, water is produced as a byproduct of oil extraction. This water, often referred to as produced water, must be managed properly. High-pressure pumps play a vital role in water reinjection operations, where water is injected back into underground formations either to maintain reservoir pressure or for disposal purposes.

Reinjection helps sustain oil production by balancing the pressure within the reservoir. High-pressure pumps ensure that the water is reinjected at sufficient pressure to counteract declining natural reservoir pressure, helping to push the remaining hydrocarbons toward production wells. In addition to maintaining reservoir pressure, water reinjection can also reduce the environmental impact of oilfield operations by minimizing surface water disposal.

Fluid Transfer Over Long Pipelines

Another key application of high-pressure pumps in onshore oilfields is fluid transfer over long pipelines. Onshore oilfields often require the movement of large quantities of oil, water, or other fluids across vast distances from the wellhead to processing facilities or storage tanks. High-pressure pumps provide the force needed to transfer these fluids efficiently over extended pipelines.

Due to the considerable distance and friction encountered along these pipelines, the pumps must generate enough pressure to overcome these challenges. High-pressure pumps ensure that the fluids maintain a steady flow, regardless of the length of the pipeline or any elevation changes along the route. This reliable fluid transfer is essential for continuous production operations and effective resource management.

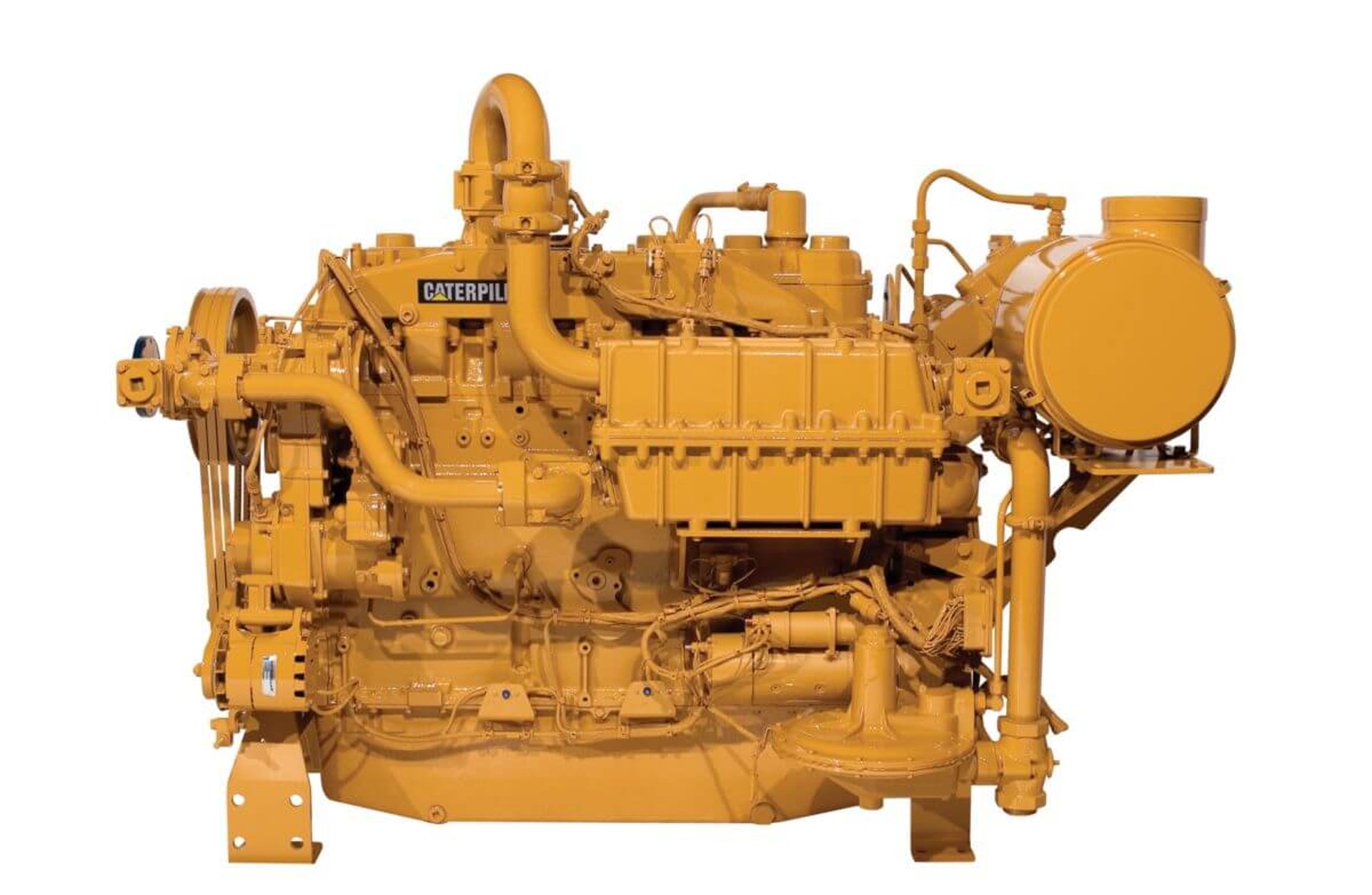

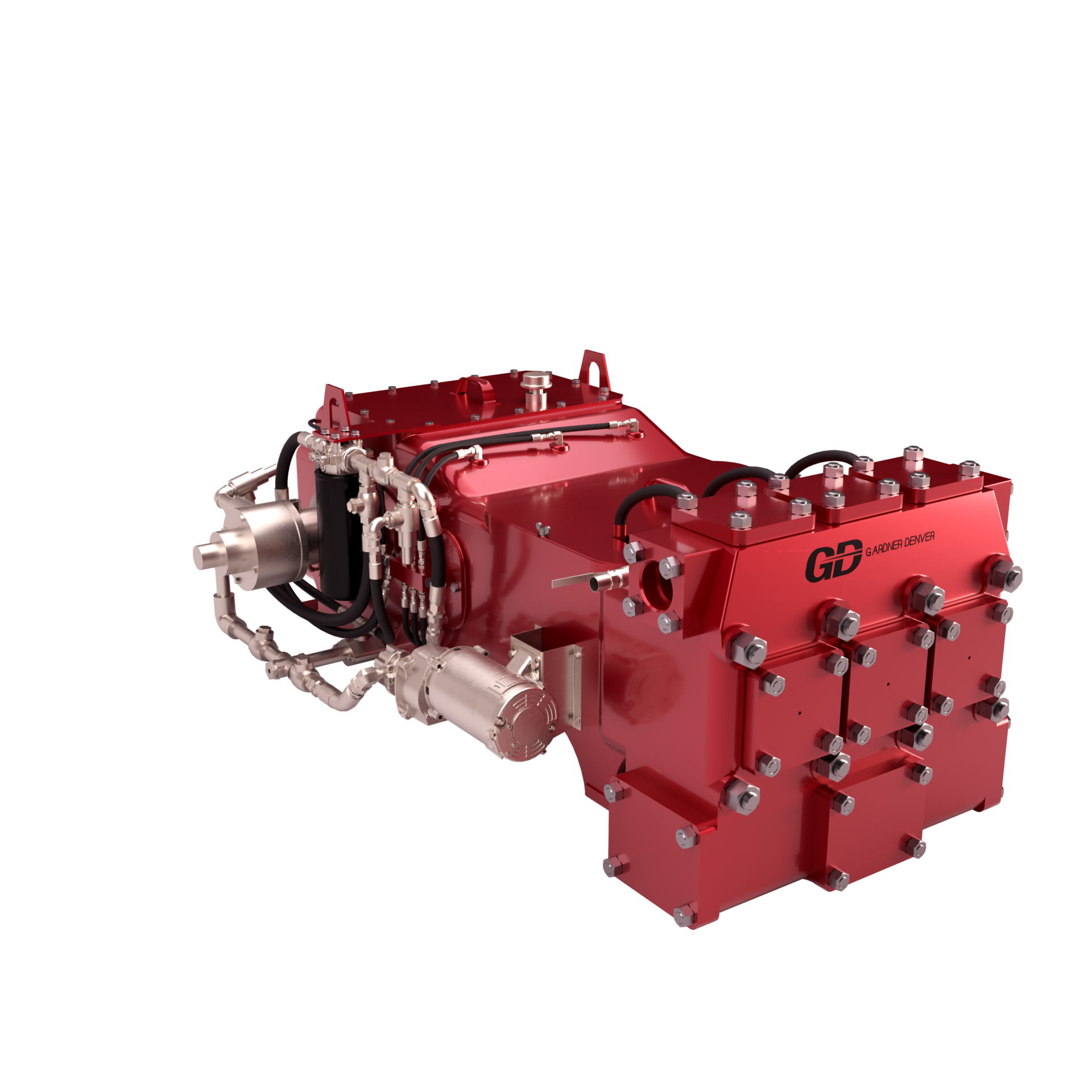

Gardner Denver is one of our high-pressure pump suppliers when building a customer’s high-pressure pumping system.

Gardner Denver manufactures high-pressure pumps specifically for the fracking industry, where fluids need to be pushed out at pressures over 7,500 PSI to break through geological formations.

We also supply the lesser-known, high-quality brand Kerr Pumps. Their high-pressure pumps can operate at pressures over 2,500 PSI.