Power Flow has been an Arrow Engine distributor since 1977.

As an Arrow distributor, we supply the onshore oilfield production industry with Arrow’s various compressors, engines, engine replacement parts, and accessories.

Arrow Engine’s Oil Field Advantages

Continuous Duty Engines

Arrow engines are designed for continuous duty. 24/7 dependable performance just how you need it.

Arrow’s heavy duty design features:

- a heavy flywheel

- a governor speed control

- pressurized full flow lubrication system to assure continuous operation

Arrow Engines are Oilfield Tough

Nearly 100,000 Arrow engines power pumping jacks in oilfields from Canada’s frozen tundra to the mountains of South America. From the Middle Eastern deserts to the jungles of Indonesia.

Many of the original Arrrow engines built in the 1940’s are still running today.

Tough means they work harder, longer.

Powered by Field Gas: Use Your Gas By-product to Fuel Arrow Engines and Compressors

Arrow engines run on a variety of low BTU gases. Arrow Engines run on typical gas by-product in the field.

-

natural gas

-

wellhead gas

-

methane

-

butane or propane

Whether in remote jungles or civilization, locally available gas costs much less than bringing in liquid fuel or even electric power.

Arrow Gas Engines Offer Cheaper Operation than Electric

Studies performed in the U.S. have shown that operating costs for Arrow engines can be as low as half the cost for equivalent HP electric motors.

Since every area is different, you owe it to yourself to compare the costs in your area.

Easy Maintenance

Arrow engines are designed for easy, quick field maintenance. The oil level can be checked and adjusted while the engine is running. Easy access enables replacing piston rings and wet cylinder sleeves* in the field; and Arrow parts are interchangeable from the first model made. Ignition-Starfire Solid State Ignition Systems are standard for Single Cylinder engines and optional on Twin Cylinder engines. Also available as options are high tension or solid state magnetos, or Altronic ignition systems.

Arrow Engine Company’s website offers specific tech specs on the following:

- Single & Double Cylinder Natural Gas Engines: 2 HP to 78 HP

- Multi Cylinder Natural Gas Engines: 40 HP to 236 HP @ 1800 RPM

- Gen Sets: Natural Gas and Diesel 5 KW to 200 KW

- Chemical Pumps – Solar, Electric, Air/Gas – Plunger Design

- Compressors – Natural Gas Reciprocating, 5 to 500 HP, 3600 psig & 4 MMSCFD

Power Flow, the Arrow Distributor provides Arrow replacement parts, too!

For assistance with replacement parts from the following manufacturers, please Contact Us:

- Ajax®: EA-22, EA-30, E-30, E-42, DP-60/70/80/115/160/230

- Caterpillar: G3304/06, G3406/08/12, G3508/12/16/20, G379, G398/99, G353/G342

- Cummins: G855, GTA12, G8.3G, G5.9, L10240/280

- Fairbanks: ZC-118/208/346/503/739

- Gemini: G26, G40, M-Series Compressor Parts

- Waukesha: VHP: P9390, F3521, L7042, L5790

- Waukesha: Intermediate: 140G/F554, 145G/F817, F1197

- Waukesha: VGF: H24G, F13G

- Witte: B12, E15/20, F32, F412, WD-14/98

- White Superior: 6G-825, 8G-825, 12G-825, 16G-825

- Ariel: Compressor Parts

Slow-High Speed Natural Gas Engines (New)

- VR Series Natural Gas, propane, 17-215 HP (Continuous)

- C Series Four Cycle Gas Engines 75 HP

VRG Series Engines

- Most popular ignition systems available

- Capable of operating on most spark-ignited fuels

- Gasoline carburetion or demand regulator for gaseous fuel

- More than 40 years history of operating on natural and well head gas

Outstanding Features

- Vertical in-line adjustable fan bracket

- 4 groove crankshaft pulley; 2 groove fan; 1 groove water pump; 4th groove auxiliary

- Flywheel – SAE no. 3 w/ring gear and SAE no. 3 housing

- Lifting eyes – front and rear

- Full Pressure lube oil system with full-flow oil filter

- Exhaust manifold with top or rear outlets

- 10% regulated speed by the mechanical governor – other governor options available

- Heavy-duty, deep-skirted crankcases

- Forged steel, dynamically balanced, counterweighted crankshafts with hardened journals

- Forged steel connecting rods

- Seven main bearings

- Replaceable precision main and rod bearings

- Overhead valve cylinder heads with replaceable

Other Outstanding Features

- Altitude:

- NA engines – deduct 3% for each 1000′ (305m) above 1500′ (457m) (continuous duty), or above 500′ (152m) (intermittent duty).

- Temperature:

- Deduct 1% for every 10°F. (6°C.) above 100°F (38°C.) (continuous duty), or above 85°F. (intermittent duty).

- Intermittent Rating (I):

- The highest load and speed that can be applied under specific conditions of varying load and/or speed.

- Continuous Rating (C):

- The load and speed that can be applied without interruption except for normal maintenance.

All ratings corrected to 500′ (152 m) altitude, 29.38″ (746 mm) Hg. and temperature of 85° F. (29° C.). Natural gas ratings are based on use of 900 BTU (33.5 J/cm3) LHV gas. HD-5 propane ratings are based on use of 2335 BTU (87 J/cm3) LHV fuel.

C Series 4-Cycle Engines

Advantages

Continuous Duty

Arrow engines are designed for continuous duty 24 hours a day, day after day. They deliver reliable performance when you need it. Arrow’s heavy-duty design features a heavy flywheel, a governor speed control, and a pressurized full-flow lubrication system to assure continuous operation.

Oilfield Tough

Over 75,000 Arrow engines power pumping jacks in oilfields from the frozen tundra of Canada to the mountains of South America, from the deserts of the Middle East to the jungles of Indonesia. Many of the original engines built in the 1940s are still running today. Tough means they work harder and longer.

Field Gas Fueled

Arrow engines run on a variety of low BTU gases.

natural gas, wellhead gas, methane, butane or propane. Whether in remote jungles or in civilization, locally available gas fuel frequently costs much less than bringing in liquid fuel or electric power.

Economical Operation

Studies performed in the U.S. have shown that operating costs for Arrow engines can be as low as half the cost for equivalent HP electric motors. Since every area is different, you owe it to yourself to compare the costs in your area.

Easy Maintenance

Arrow engines are designed for easy, quick field maintenance. The oil level can be checked and adjusted while the engine is running. Easy access enables replacing piston rings and wet cylinder sleeves* in the field, and Arrow parts are interchangeable from the first model made. Ignition-Starfire Solid-State Ignition Systems are standard for Single-Cylinder engines and optional on Twin-Cylinder engines. Also available as options are high-tension or solid-state magnetos or Altronic ignition systems.

Arrow Engineered Improvements

Improvements to the Heavy-Duty C-Series Engines since May 1977 (most all can be retrofitted to earlier models using current kits):

- Heavy steel fabricated sub-base

- Full-flow oil system with spin-on filter

- A mounting pin for Arrow 990

- Portable starter added to sub-base

- Bronze crankshaft gears for C-46 through C-106

- Arrow oil filler added to engine (ASP-1)

- O-ring modified rocker shaft plugs

- Reliable stainless steel braided oil lines

- Ball rod ends standard on all Arrow engine models

- Stainless steel water filler added as standard (ASP-3A)

- Vibration-free cross braced radiator shells

- Common muffler made standard on C-Series engines

- Lifting eyes added to facilitate engine handling

- Newly increased engine horsepower with the change to Impco 100 and 200 carburetors

- All Arrow Engines are either electric 12-volt ring gear starting or blow down air-gas starting systems

- Added instrument panel to house starter switch, cannon receptacle, oil pressure gauge and shut down

- Cylinder heads modified to accept Impco carburetors without using cross flange adapter

- Improved ring gear starter mounting on new flywheel (eliminated separate ring gear carrier)

- Added QD hub to flywheel for safety in de-mounting

- Latest trochoidal oil pumps standard

- Oil pressure bypass valve included in oil pump assembly

- Optional renewable oil filter available

- A wiring harness is used to combat weather hazards

- Optional cover for Arrow electric starter motor available (prevents water from damaging starter motor)

- Starfire ignition is standard (C.D.I. for long life) and operates in the rain

- Redesigned breather system to improve crankcase ventilation and reduce emissions of crankcase vapors into the atmosphere (244BC)

- Solderless pressure condensing radiators with steel top tanks, bottom headers and replaceable

- Cores made standard on C-46 through C-106 – optional on C-255

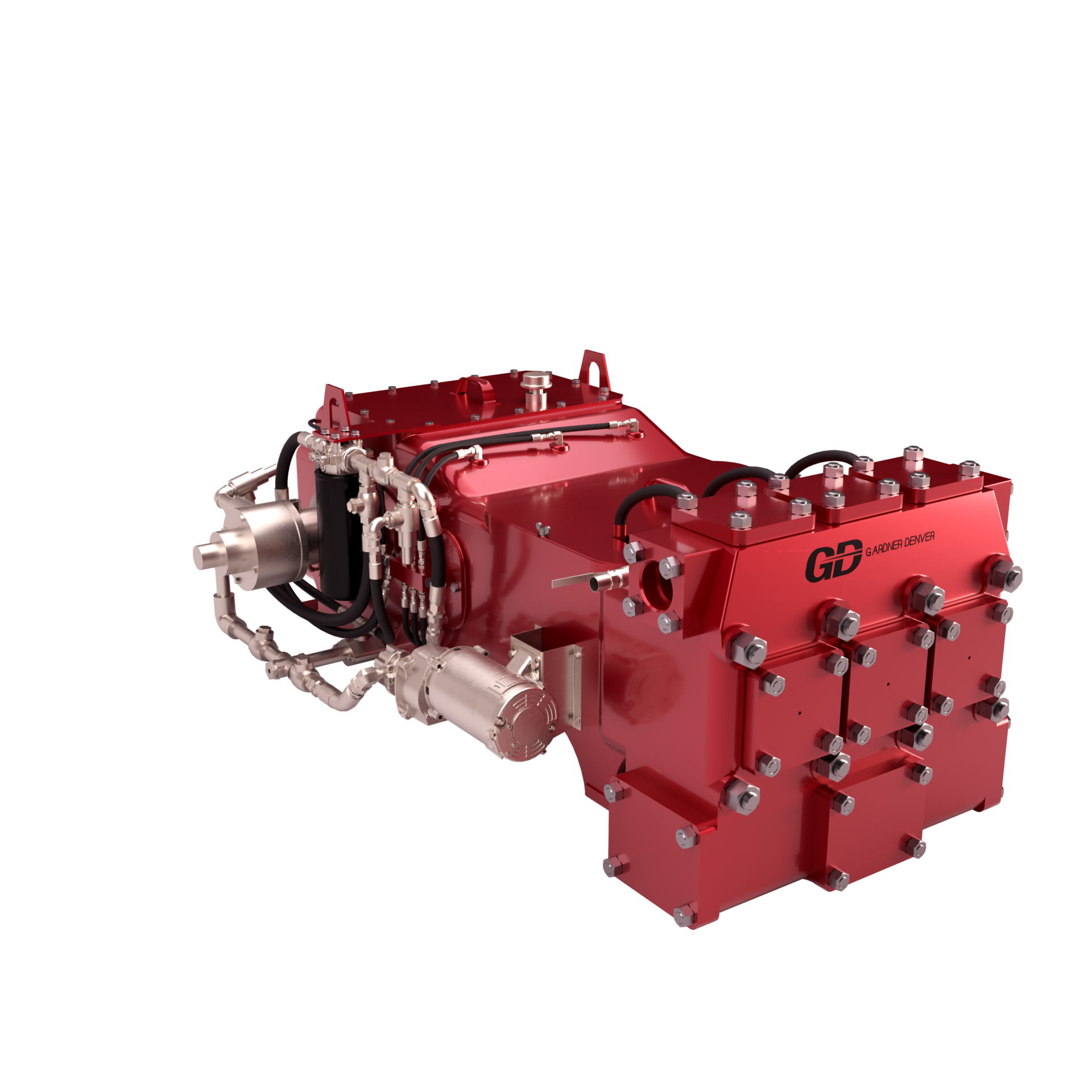

Arrow Engine’s KP-Series

The KP-Series line of multi-cylinder engines can accommodate a variety of applications, both common and unusual. Engines are available naturally aspirated and turbo charged. The RPM runs between 900 and 1,800, with HP from 15-197. (A-Series engine line only available as parts.)

Power Units

As and Arrow Distributor with engineers on hand, we can also package these as power units that have everything you require. Arrow engines are perfect for rotational or hydraulic pumping units, hydraulic skids for PC pumps, or for any form of artificial lift where independent natural gas power is needed.

Power Ratings

| Intermittent | Continuous | |||||||||||||

| MODEL | PEAK INTERMITTENT | BRAKE HORSEPOWER AT SPEEDS INDICATED (S.A.E.) | ||||||||||||

| TORQUE @ 1800 RPM | 900 | 1000 | 1200 | 1400 | 1600 | 1800 | ||||||||

| Spark Ignited | FT.LB. | N*M | ||||||||||||

| KP3 | 125 | 169 | 24 | 21 | 26 | 23 | 30 | 28 | 35 | 31 | 40 | 35 | 42 | 38 |

| KP4 – Natural Gas | 175 | 237 | 59 | 54 | ||||||||||

| G54 – Natural Gas | 220 | 298 | 29 | 26 | 36 | 33 | 47 | 42 | 58 | 52 | 67 | 60 | 75 | 68 |

| KP3TA | 292 | 396 | 90 | 70 | 100 | 75 | ||||||||

| KP6 – Natural Gas | 275 | 373 | 52 | 47 | 59 | 53 | 68 | 61 | 78 | 70 | 86 | 78 | 94 | 85 |

| KP6TA – Natural Gas | 575 | 780 | 197 | 148 | ||||||||||

Get a Quote

Get Your Arrow Engines and Parts

As an Arrow Engine distributor, Power Flow supplies your need for slow-speed natural gas engines, four and six-cylinder engines, generator sets, and natural gas compressors.

We pack and ship Arrow products and accessories around the world.

We’re an Arrow Distributor to other industrial markets, too, wherever pumps are used, even beyond the onshore oil production market.